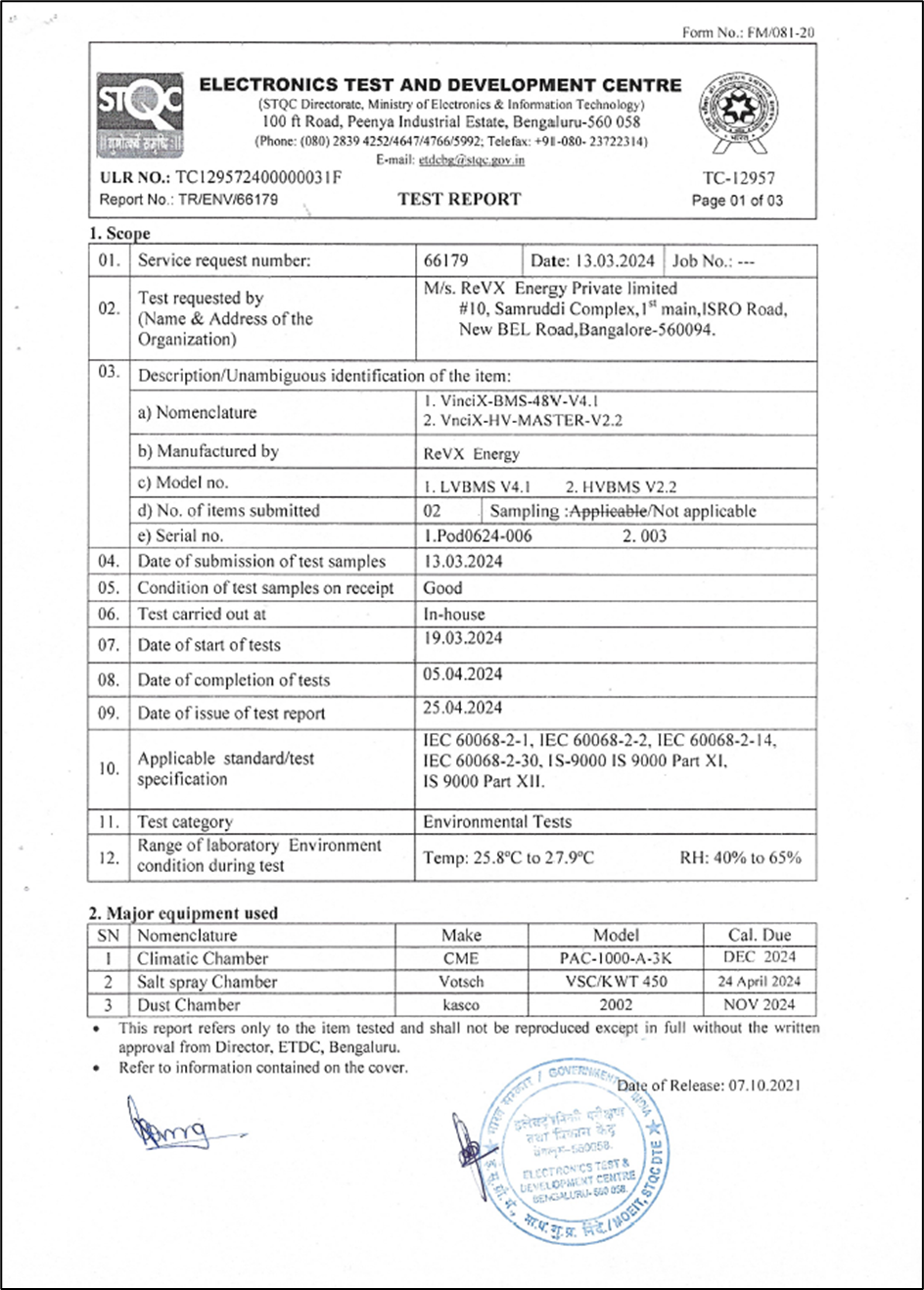

4. Environmental Test¶

Following tests are done to increase safety and reliability of DUT.

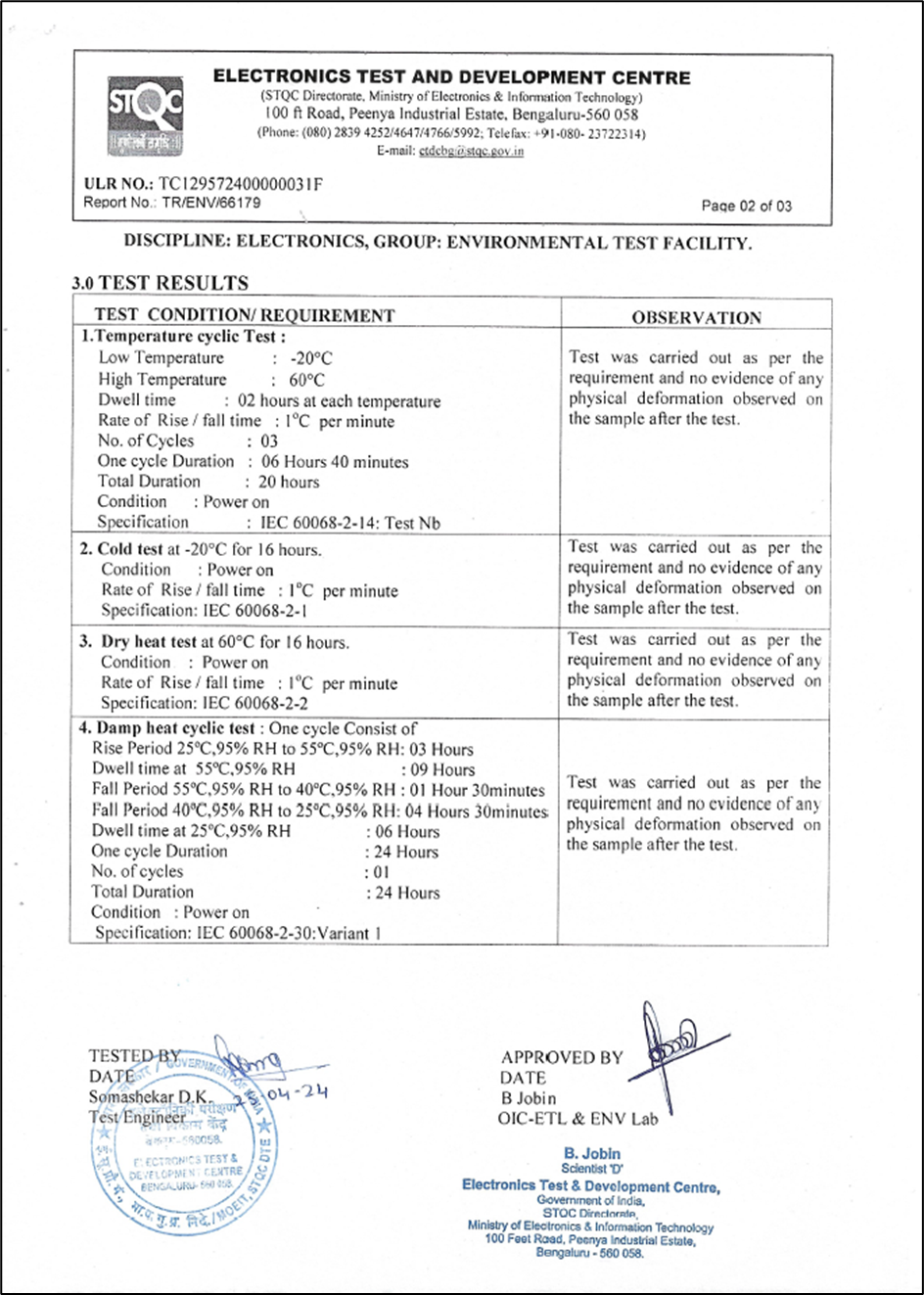

4.1. Temperature Cycling:¶

Applicable Standard: IEC 60068-2-14 - Test N: Change of temperature

Operating Mode: 2.2

Test Temperature: -20C to +60C

No of Cycles: 3

Dwell Time: 2 hrs

Step: 1C/min

Pass Criteria: The unit should be functional without any issues, Functional state should be A.

4.2. Dry Temperature Test:¶

Applicable Standard: IEC 60068-2-14 - Test N: Change of temperature

Operating Mode: 2.2

Test Temperature: -20C to +60C

No of Cycles: 3

Dwell Time: 2 hrs

Step: 1C/min

Pass Criteria: The unit should be functional without any issues, Functional state should be A.

4.3. Cold Test:¶

Applicable standards: IEC 60068-2-1 - Test A: Cold

Test Temperature: -20c

Dwell Time: 16 hrs

Test Method: Decrease the temperature from 25C at 1C/min till -20C and keep the unit running at -20C for 16 hrs and bring the temperature back to 25C at 1C /min slope. Take measurements at -20c and 25C. Plot the graph and attach.

Pass Criteria: The unit should be functional without any issues.

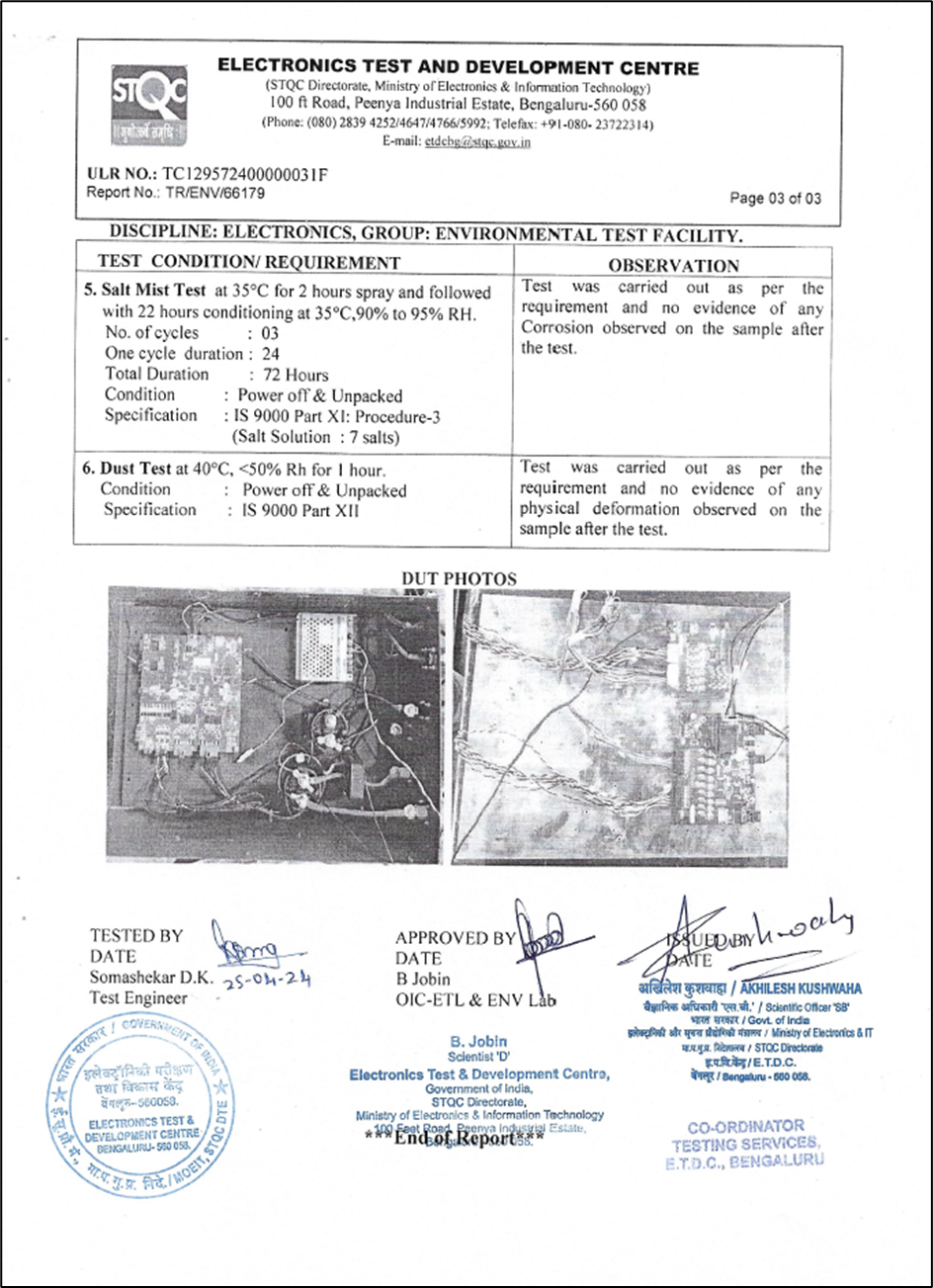

4.4. Dust Test:¶

Applicable standards: IS 9000 (Part XII)

Test Temperature: 40C

Operating Mode: 1.1, is selected, as per the standard

CHARACTERISTICS OF DUST

- The dust used for this test shall be dry. It shall be heated to 40 ± 3°C before the agitation of the dust in the chamber is commenced.

-

The dust shall conform to the following requirements:

- Physical Characteristics — The physical characteristics of the dust shall be as given below:

- 100 percent dust shall pass through 150 micron IS Sieve.

- 98 ± 2 percent dust shall pass through 106 micron IS Sieve.

- 90 ± 2 percent dust shall pass through 75 micron IS Sieve.

- 75 ± 2 percent dust shall pass through 45 micron IS Sieve.

-

Chemical Composition — The chemical composition of the dust shall be as given in Table 1.

SL No Substance Percentage by Weight 1 SiO2 97 to 99 2 Fe2O3 0 to 2 3 Al2O3 0 to 1 4 Tio 0 to 2 5 MgO 0 to 1 6 Ignition Losses 0 to 1

- Physical Characteristics — The physical characteristics of the dust shall be as given below:

-

INITIAL MEASUREMENTS

- The item shall be visually inspected, and electrically and mechanically checked, as required by the relevant specification.

- The Sample Board should be in working condition before testing.

- CONDITIONING

- The item shall be subjected to the test in its ' unpacked and switched-off ' condition.

- The item under test, while being under the laboratory atmospheric conditions shall be introduced into the chamber, the latter also being under the same conditions. Sufficient quantity of dust shall also be introduced into the chamber.

- The temperature of the chamber shall then be raised to a value of 40 ± 3°C. The relative humidity shall be maintained at a value not exceeding 50 percent.

- After temperature stability has been attained, the test item shall then be subjected to a stream of dust laden air for a period of 1 hour. During this period the dust concentration shall be maintained as per the standard.

- After 1 hour, the circulation of dust shall then be discontinued and the temperature of the chamber shall be restored to the laboratory atmospheric conditions.

- RECOVERY

- The item shall be removed from the chamber and allowed to remain under standard recovery conditions for a period of 2 to 4 hours.

- FINAL MEASUREMENTS

- The item shall be visually inspected as specified and any local accumulation of dust shall be noted. If required, the item shall then be electrically and mechanically checked.

- The accumulated dust shall be removed before electrical and mechanical checks are made. The dust shall be removed by brushing, wiping or shaking. Under no circumstances shall the dust be removed by an air blast or oy vacuum cleaning.

- Pass Criteria: After the exposure to dust the item shall be checked for its operation. The test sample should meet Functional Status of at least B. Pictures of test specimen shall be attached.

4.5. Salt Mist:¶

Applicable standards: IS : 9000 ( Part XI ) - 1983

Test Temperature: Room temperature

Procedure: 3

Operating Mode: 1.1, is selected,

The item under test shall be subject to this test in its 'unpacked' and 'switched-off' condition. Three test procedures are specified for this test.

(As per IS 9000 Part XI, Test Procedure 1 is applicable to component type items. Test Procedures 2 and 3 are applicable to equipment type items. Where an item is likely to be exposed to severe salt contamination conditions, Test Procedure 2 may be referred and in less exacting conditions where a salt laden atmosphere will occasionally exist. Test Procedure 3 may be preferred. The relevant specification shall specify any of the three test procedures, as necessary.)

The Test Procedure 3 is selected as the product is always a part of the battery and IP of the battery is Min IP65.

The Salt composition is as per the below table, as per the the standard.

| Ingredient | Quantity Per 1 Litre of Solution |

|---|---|

| Sodium chloride (Na CI ) | 26.5 g |

| Magnesium chloride ( MgCl 2 ) | 2.4 g |

| Magnesium sulphate ( MgS0 4 ) | 3.3 g |

| Calcium chloride ( CaCl 2 ) | 1.1g |

| Potassium chloride ( KC1 ) | 0.73g |

| Sodium bicarbonate ( NaHCO s ) | 0.2g |

| Sodium bromide ( NaBr ) | 0.28g |

| Distilled water | To make up 1 litre of solution |

Method: As per the Procedure 3 of IS 9000 Part XI

- The item under test shall be positioned in the chamber in its normal operational attitude at the laboratory atmospheric conditions.

- The item shall be exposed to a continuous salt laden atmosphere in the chamber for a period of 2 hours under the laboratory temperature. The quantity of salt solution sprayed shall be approximately 10 litres per m 3 of chamber volume per 24 hours.

- The composition of the salt solution shall be as specified in the table above.

- At the end of the period specified in 7.5.2, the item shall be removed from the chamber and transferred to a damp heat chamber maintained at a temperature of 35 -± 3°C and relative humidity of 90 to 95 percent and stored under these conditions for a period of 22 hours.

- The procedure specified in 2 to 4 constitutes one cycle. The item shall be subjected to a total of 3 consecutive cycles.

Final Visual Examination:

For Procedures 3, at the end of the conditioning period specified in 1 and 5, the items, unless otherwise specified by the relevant specification, shall be washed in running tap water for five minutes, rinsed in distilled water or demineralized water and then shaken by hand or subjected to an air blast to remove droplets of water, then dried for one hour at 55 ± 2°C and allowed to cool under recovery conditions for not less than 1 hour nor more than 2 hours. The relevant specification shall specify, if required, other methods to be used for washing and drying. The items shall be stored under recovery conditions for not less than one hour and not more than 2 hours. The temperature of the water used for washing shall not exceed 35°C.

Recovery

The items shall then be subjected to recovery under standard atmospheric conditions for testing for a period of 2 to 4 hours, unless otherwise specified in the relevant specification.

FINAL MEASUREMENTS and Pass Criteria

The items shall then be visually inspected and electrically and mechanically checked. There should not be any corrosion of connectors, soler joints, components, leads of the components, copper pads of all the smd and through hole components, exposed copper layers etc. The unit should work as per the design Minimum Functional Status B should be satisfied. Photos of the specimen to after and before test to be attached.